EVA foam is the backbone of midsoles and outsoles in casual footwear, sports shoes, safety shoes, and military boots. Its lightweight structure, cushioning performance, and processing flexibility have made it the industry’s default choice for decades.

However, as footwear design trends evolve toward thinner soles, lighter weights, and longer service life, many brands and manufacturers are encountering recurring performance failures during aging and real-world use:

• Foam collapse after repeated compression

• Heat shrinkage after molding or storage

• Rebound loss and permanent deformation

• Reduced tensile strength after flexing

These issues not only compromise comfort and durability but also create serious brand and warranty risks, especially in mid- to high-end footwear markets where long-term performance is a key differentiator.

To address these challenges, SEBS-modified EVA foam has become the mainstream solution. Yet, in many demanding applications, SEBS modification alone is proving insufficient.

This article examines why SEBS-modified EVA foams still fail, the structural reasons behind shrinkage and rebound loss, and how the Si-TPV 2250 Series introduces a new, more stable modification strategy for high-performance EVA foams.

SEBS-Modified EVA Foam: The Mainstream Solution — and Its Limits

SEBS-modified EVA foaming has become the mainstream solution to enhance elasticity and low-temperature toughness. By introducing an elastomeric phase, SEBS improves rebound performance, flexibility, and aging resistance. However, SEBS also has inherent limitations that become increasingly obvious when footwear designs push for thinner midsoles and longer life cycles:

Oil migration from oil-extended SEBS occurs during foaming, causing surface stickiness, unstable cell walls, and increased shrinkage.

SEBS improves elasticity but does not fundamentally stabilize foam cell structure, especially under thermal and mechanical stress.

High rebound does not guarantee rebound retention, particularly after repeated compression cycles and high-temperature exposure.

Therefore, even SEBS-modified EVA foam may still experience long-term collapse, shrinkage, and permanent deformation—leading to customer complaints and warranty issues.

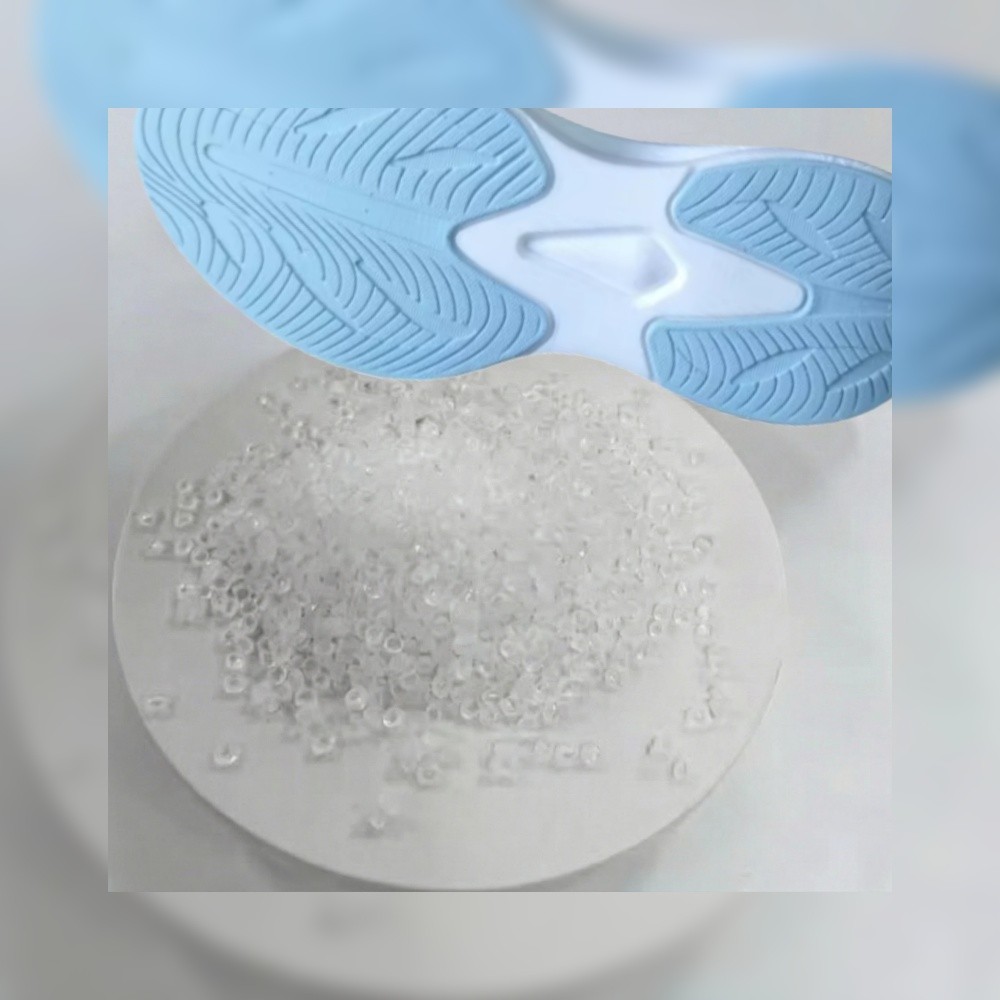

Dynamic vulcanized thermoplastic silicone-based elastomer (Si-TPV) represents a fundamentally different approach.

SILIKE’s Si-TPV 2250 Series is an eco-friendly silicone-based thermoplastic elastomer modifier that redefines EVA chemical foaming technology, ensuring superior uniformity and consistency in foams. By eliminating chemical migration and providing an adjustable foaming ratio, Si-TPV enhances production efficiency, reduces energy consumption, and improves foam performance.

Compared with SEBS, Si-TPV Eco-Friendly Thermoplastic Elastomer Modifier Offers the Following Advantages in EVA Foaming

1. Improved Elasticity & Rebound Retention

Compared with traditional fillers like talc or anti-abrasion agents, Si-TPV enhances elastic recovery and long-term rebound retention. It helps EVA foam maintain cushioning performance over extended use, even under repeated compression cycles.

2. Reduced Heat Shrinkage Without Oil Migration

Si-TPV does not rely on oil extension, so there is no oil migration. Its intrinsic elasticity helps release internal thermal stress during foaming and cooling, significantly reducing post-molding shrinkage and dimensional instability.

3. Enhanced Wear Resistance and Anti-Slip Performance

Si-TPV 2250 Series acts as a functional EVA modifier, improving both abrasion resistance and slip resistance. In DIN abrasion tests, wear volume can be reduced substantially—supporting durable high-wear footwear applications.

4. Higher Crosslinking Density & Structural Stability

Si-TPV can participate in crosslinking reactions, contributing to a higher crosslink density. This improves tensile strength, fatigue resistance, and long-term compression stability.

5. Heterogeneous Nucleation for Finer Foam Cells

Uniform dispersion of Si-TPV particles promotes heterogeneous nucleation during foaming, resulting in finer and more uniform cell structures. This helps maintain mechanical consistency and foam stability.

6. Reduced Compression Set Across Temperatures

Si-TPV offers excellent high and low-temperature resistance, improving compression deformation performance in higher hardness EVA foam materials and ensuring stable cushioning under extreme conditions.

7. Enhanced Color Saturation

Functional groups in Si-TPV improve pigment interaction, resulting in brighter, more uniform colors for premium footwear.

Comparative Performance: Si-TPV 2250-75A vs. SEBS in EVA Foam (40A Hardness)

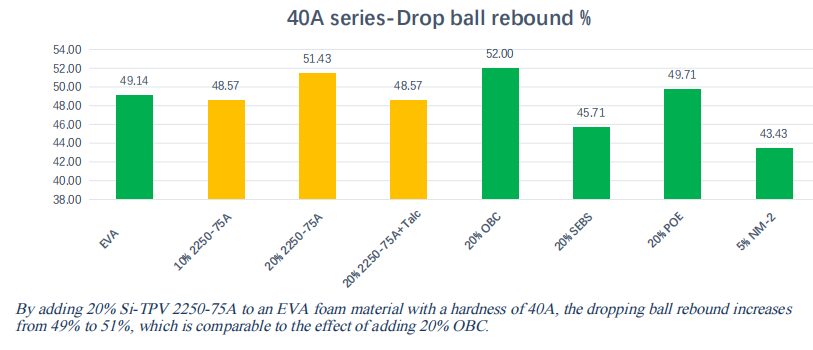

1. Drop Ball Rebound

Adding just 20% Si-TPV 2250-75A to EVA foam (40A hardness) enhances rebound resilience from 49% to 51% — Better than SEBS, achieving results nearly identical to 20% OBC, while offering improved processing and sustainability benefits.

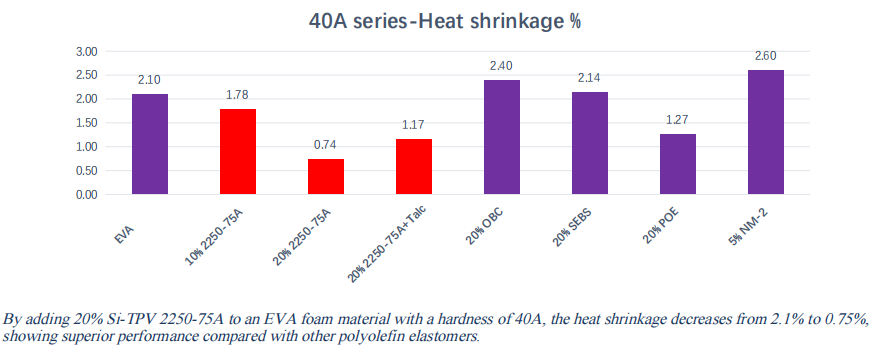

2. Heat Shrinkage

Adding 20% Si-TPV 2250-75A to EVA foam (40A hardness) reduces heat shrinkage from 2.1% to just 0.75% — delivering significantly better dimensional stability than SEBS-modified systems.

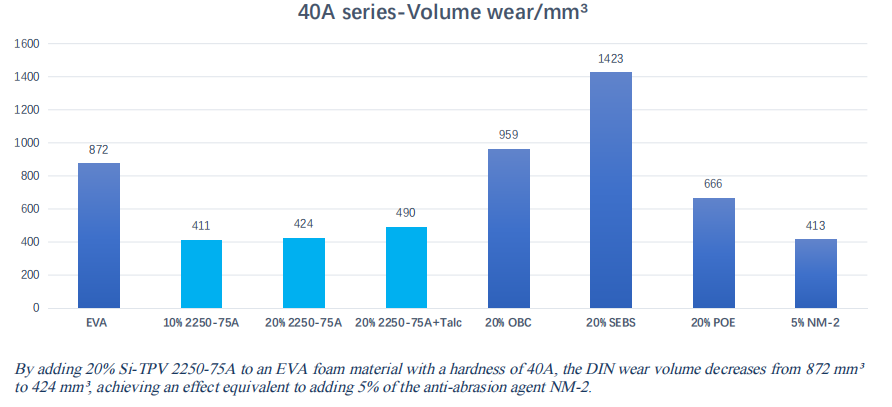

3. DIN Wear Volume

Incorporating 20% Si-TPV 2250-75A into EVA foam (40A hardness) reduces DIN wear from 872 mm³ to 424 mm³ — delivering abrasion resistance comparable to adding 5% anti-wear agents.

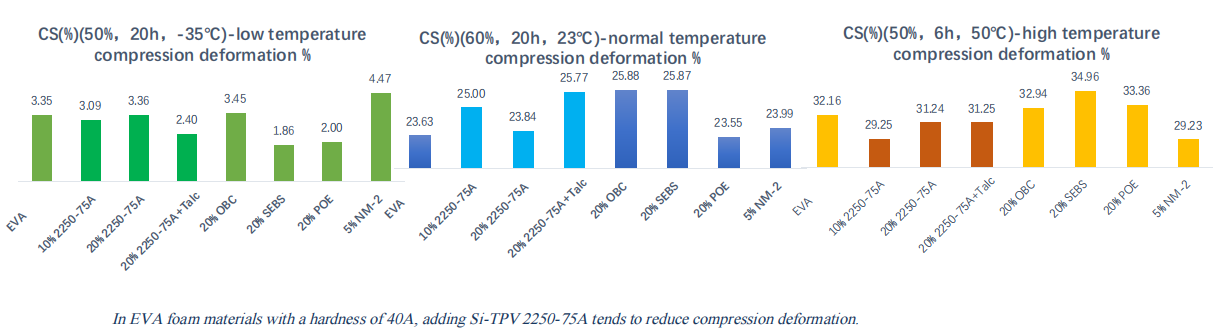

4. Compression Deformation

In EVA foam (40A hardness), the addition of Si-TPV 2250-75A helps reduce compression deformation, enhancing shape recovery and long-term durability.

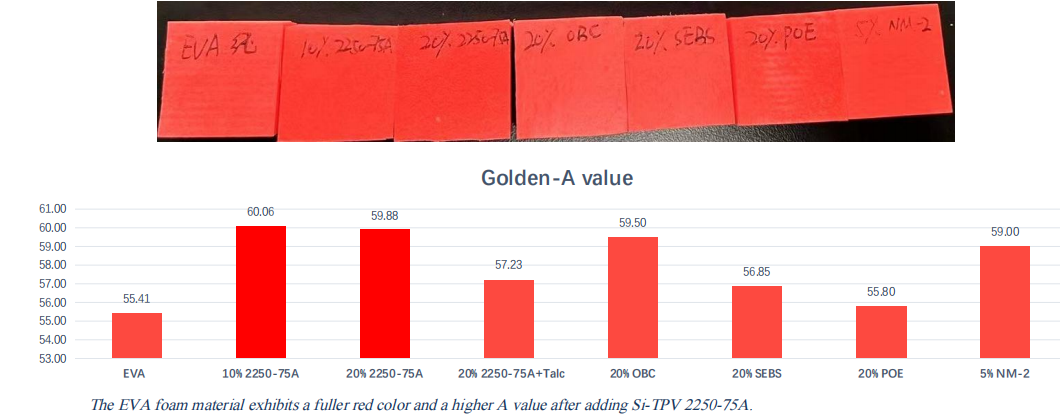

5. Color Difference

After incorporating Si-TPV 2250-75A, the EVA foam shows a richer red tone and an increased A value, indicating richer color tones enhance visual appeal for high-end footwear.

Si-TPV Modifier for EVA Foam: Application Recommendations & SEBS Alternative

The Si-TPV 2250 Series is designed for EVA foam midsoles and outsoles that require long-term rebound stability, reduced shrinkage, and enhanced wear resistance.

It can be used independently or in synergy with SEBS, depending on performance targets, processing conditions, and cost considerations.

For high-performance sports footwear, safety shoes, military boots, and other demanding applications, Si-TPV 2250 Series provides a stable upgrade path for EVA foams that require high rebound, comfort, abrasion resistance, and long-term dimensional stability — without the common oil-migration risks associated with traditional SEBS-modified systems.

Rather than acting as a simple additive, Si-TPV 2250 Series functions as a next-generation EVA foam modifier, creating a more durable performance for lightweight, comfortable footwear.

Get Started with Si-TPV 2250 Series — Technical & Procurement Support

Whether you are evaluating a SEBS alternative, optimizing EVA foam formulations, or scaling high-performance footwear production, our technical team can support you with:

Si-TPV 2250 Series EVA foam modifier samples

EVA foam formulation optimization

Processing and foaming parameter guidance

Ultra-light, elastic, and eco-friendly EVA foaming material solutions

Phone: +86-28-83625089

Email: amy.wang@silike.cn

Website: www.si-tpv.com