Thermoplastic Polyurethane (TPU) is a versatile material known for its durability and resilience. However, in certain applications, there may be a need to reduce the hardness of TPU granules while simultaneously enhancing abrasion resistance.

Strategies to achieve reduce the hardness of TPU and improve abrasion resistance balance.

1. Blending with Softer Materials

One of the most straightforward ways to reduce TPU hardness is by blending it with a softer thermoplastic material. Common options include TPE (Thermoplastic Elastomers) and softer grades of TPU.

Careful selection of the softer material and the ratio at which it is blended with TPU can help achieve the desired level of hardness reduction

2.A Fresh Approach: Blending TPU Particles with Novel Soft Material Si-TPV

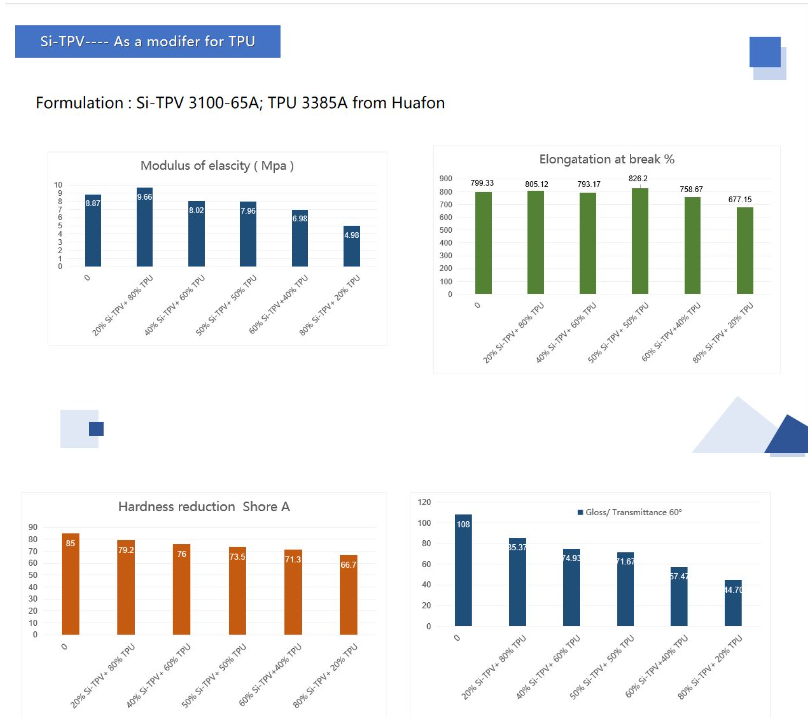

Blending the 85A TPU granules with SILIKE launched soft Material Si-TPV( dynamic vulcanizate thermoplastic Silicone-based elastomer), This method strikes the desired balance between hardness reduction and increased abrasion resistance,without compromising its other desirable properties.

Way to reduce the hardness of the TPU particles, Formula and Evaluation:

The addition of 20% Si-TPV to the Hardness of 85A TPU reduces hardness to 79.2A

Note: The above test data is our lab practical test data, and can not be understood as a commitment of this product, the customer should be tested based on their own specific.

However, Experimentation with different blending ratios is common, aiming to achieve the optimal combination of softness and abrasion resistance.

3. Incorporating Abrasion-Resistant Fillers

To enhance abrasion resistance, experts suggest incorporating specific fillers like carbon black, glass fibers, silicone masterbatch, or silicon dioxide. These Fillers can bolster the TPU's wear-resistance properties.

However, careful consideration should be given to the quantity and dispersion of these fillers, as an excessive amount might affect the material's flexibility.

4. Plasticizers and Softening Agents

As a method to reduce TPU hardness, TPU Manufacturers might use plasticizers or softening agents. It is important to select a suitable plasticizer that can lower hardness without compromising abrasion resistance. Common plasticizers used with TPU include dioctyl phthalate (DOP) and dioctyl adipate (DOA). Care must be taken to ensure that the chosen plasticizer is compatible with TPU and does not negatively impact other properties such as tensile strength or chemical resistance. In addition, The dosage of plasticizers should be meticulously controlled to maintain the desired balance.

5. Fine-Tuning Extrusion and Processing Parameters

Adjusting extrusion and processing parameters is pivotal in achieving the desired combination of reduced hardness and enhanced abrasion resistance. This entails modifying parameters like temperature, pressure, and cooling rates during extrusion.

Lower extrusion temperatures and careful cooling can lead to softer TPU while optimizing the dispersion of abrasion-resistant fillers.

6. Post-Processing Techniques

Post-processing techniques like annealing, stretching, or even surface treatments can further enhance abrasion resistance without compromising hardness.

Annealing, in particular, can improve the crystalline structure of TPU, making it more resistant to wear and tear.

In conclusion, achieving the delicate balance of reduced TPU hardness and improved abrasion resistance is a multifaceted process. TPU Manufacturers can leverage material selection, blending, abrasion-resistant fillers, plasticizers, Softening Agents, and precise control of extrusion parameters to fine-tune the material properties to align with the unique requirements of a given application.

This is what you need A Winning Formula that reduces TPU Particle Hardness and Improves Abrasion Resistance!