Detail

The SILIKE Si-TPV 3100 Series is a dynamic vulcanized thermoplastic silicone-based elastomer, engineered through a specialized compatible technology that ensures silicone rubber is evenly dispersed in TPU as 2-3 micron particles under a microscope. This unique combination offers the strength, toughness, and abrasion resistance typical of thermoplastic elastomers while incorporating the desirable properties of silicone, such as softness, a silky feel, and resistance to UV light and chemicals. Importantly, these materials are recyclable and can be reused in traditional manufacturing processes.

The Si-TPV 3100 Series is designed specifically for soft-touch extrusion molding applications, exhibiting excellent abrasion and chemical resistance. It can be co-extruded with various thermoplastic engineering plastics, including PC, ABS, and PVC, without issues like precipitation or sticking after aging.

In addition to serving as a raw material, the Si-TPV 3100 Series acts as a polymer modifier and processing additive for thermoplastic elastomers and other polymers. It enhances elasticity, improves processing characteristics, and boosts surface properties. When blended with TPE or TPU, Si-TPV provides lasting surface smoothness and a pleasant tactile feel, while also improving scratch and abrasion resistance. It effectively reduces hardness without compromising mechanical properties, and it enhances aging, yellowing, and stain resistance, allowing for a desirable matte finish.

Unlike conventional silicone additives, Si-TPV is supplied in pellet form, making it easy to process like a thermoplastic. It disperses finely and uniformly throughout the polymer matrix, where the copolymer physically bonds to the matrix. This characteristic eliminates concerns about migration or "blooming," positioning Si-TPV as an effective and innovative solution for achieving silky-soft surfaces with a dry feel in TPU and other thermoplastic elastomers without requiring additional processing or coating steps.

Key Benefits

- In TPU

- 1. Hardness reduction

- 2. Excellent haptics, dry silky touch, no blooming after long-term use

- 3. Provide the final TPU product with a matt effect surface

- 4. Extends the lifespan of TPU products

Durability Sustainability

- Advanced solvent-free technology, without plasticizer, no softening oil, and odorless.

- Environmental protection and recyclability.

- Available in regulatory-compliant formulations.

Si-TPV plastic additive and polymer modifier Case Studies

The Si-TPV 3100 Series is characterized by its long-lasting skin-friendly soft touch and excellent stain resistance. Free from plasticizers and softeners, it ensures safety and performance without precipitation, even after prolonged use. This series is an effective plastic additive and polymer modifier, making it particularly suitable for enhancing TPU.

In addition to imparting a silky, pleasant feel, Si-TPV effectively reduces TPU hardness, achieving an optimal balance of comfort and functionality. It also contributes to a matte surface finish while providing durability and abrasion resistance, making it an ideal choice for a wide range of applications.

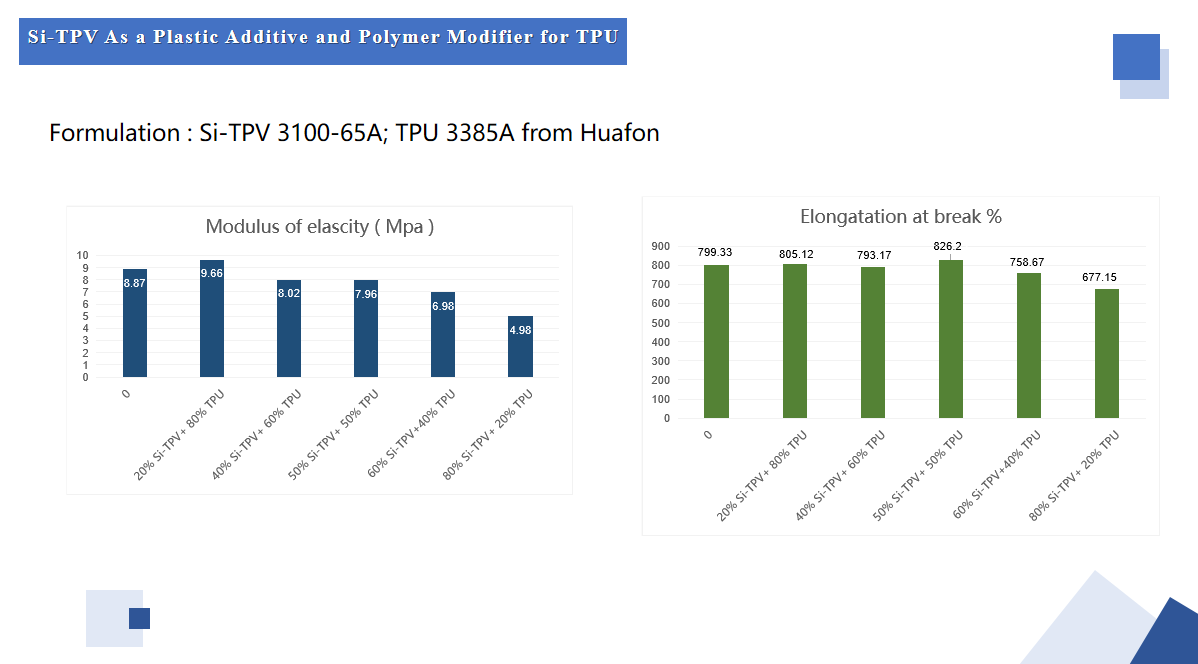

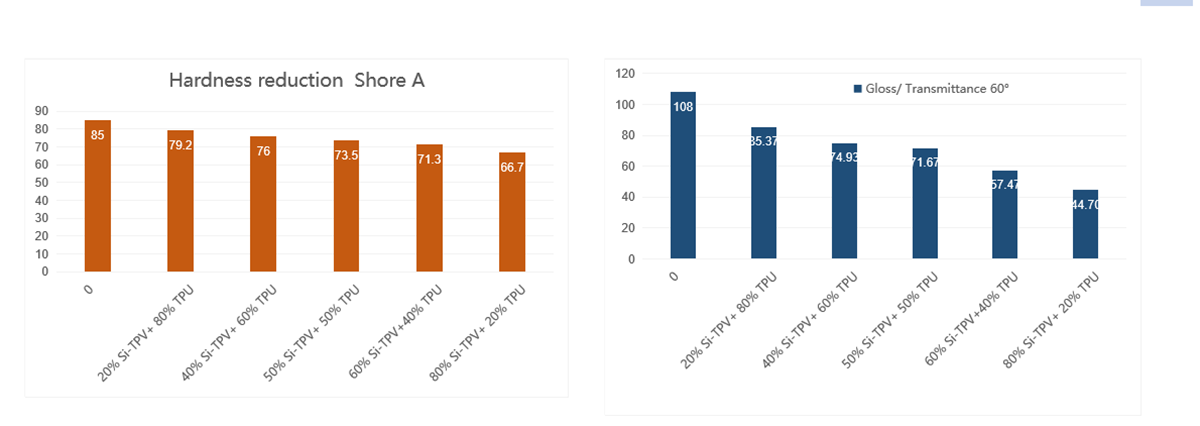

Comparing the Effects of Si-TPV Plastic Additive and Polymer Modifier on TPU Performance

Application

Surface modification of thermoplastic polyurethane (TPU) tailors its characteristics for specific applications while maintaining bulk properties. Utilizing SILIKE’s Si-TPV (dynamic vulcanized thermoplastic silicone-based elastomer) as an effective process additive and feel modifier for thermoplastic elastomers presents a practical solution.

Due to Si-TPV dynamic vulcanized thermoplastic silicone-based elastomer, provides several advantages, including a long-lasting, skin-friendly soft touch, excellent stain resistance, and the absence of plasticizers or softeners, which prevents precipitation over time.

As a silicone-based plastic additive and polymer modifier, Si-TPV reduces hardness and enhances flexibility, elasticity, and durability. Its incorporation yields a silky-soft, dry surface that meets user expectations for frequently handled or worn items, significantly expanding TPU’s potential applications.

Si-TPV blends seamlessly into TPU formulations, exhibiting fewer undesirable side effects compared to conventional silicone products. This versatility of TPU compounds opens up opportunities in various sectors, including consumer goods, automotive parts, EV charging cables, medical devices, water pipes, hoses, and sports equipment—where comfort, durability, and aesthetic appeal are essential.

Solutions:

What Manufacturers Need to Know About Modified TPU Technology and Innovative Material Solutions for EV Charging Pile Cables and Hoses!

1. Modified TPU (thermoplastic polyurethane) Technology

The modification of TPU surfaces is crucial for developing materials that can maximize performance in specific applications. First, we need to understand TPU Hardness and Elasticity. TPU hardness refers to the material’s resistance to indentation or deformation under pressure. Higher hardness values indicate a more rigid material, while lower values indicate greater flexibility. Elasticity refers to the material’s ability to deform under stress and return to its original shape upon stress removal. Higher elasticity implies improved flexibility and resilience.

In recent years, the incorporation of silicone additives into TPU formulations has gained attention for achieving desired modifications. Silicone additives play a vital role in improving the processing characteristics and surface quality of TPU without detrimentally affecting the bulk properties. This occurs due to silicone molecules’ compatibility with the TPU matrix, acting as a softening agent and lubricant within the TPU structure. This allows for easier chain movement and decreased intermolecular forces, resulting in a softer and more flexible TPU with reduced hardness values.

Additionally, silicone additives act as processing aids, reducing friction and enabling smoother melt flow. This facilitates easier processing and extrusion of TPU, enhancing productivity and reducing manufacturing costs.

GENIOPLAST PELLET 345 Siliconmodifier has gained recognition as a valuable silicone additive in TPU applications. This silicone additive has extended the range of applications for thermoplastic polyurethanes. There is considerable demand in consumer goods, automotive, medical devices, water pipes, hoses, sports equipment handle grips, tools, and more sectors for molded TPU parts that have a pleasant comfortable feel and retain their looks upon protracted use.

Silike’s Si-TPV plastic additives and polymer modifiers offer equal performance to their counterparts at a reasonable price. Tests have demonstrated that Si-TPV as novel silicone additive alternatives are viable, safe, and eco-friendly in TPU applications and polymers.

This silicone-based additive enhances long-term surface smoothness and tactile feel while reducing flow marks and surface roughness. Notably, it lowers hardness without compromising mechanical properties; for instance, adding 20% Si-TPV 3100-65A to 85A TPU decreases hardness to 79.2A. Additionally, Si-TPV improves aging, yellowing, and stain resistance, and imparts a matte finish, significantly enhancing the aesthetic appeal of TPU components and finished products.

Si-TPV is processed like a thermoplastic. unlike conventional silicone additives, it disperses very finely and homogeneously throughout the polymer matrix. The copolymer becomes physically bound to the matrix. You don’t worry about leading to migration (low ‘blooming’ ) issues.