EVA Foam Rebound Loss & Footwear Durability Challenges

Many footwear manufacturers face a long-standing challenge: EVA foam rebound loss of up to 10% after storage or extended use. This decline in resilience affects midsole comfort, reduces EVA shoe durability, and leads to higher customer complaints and return rates.

Traditional EVA + SEBS systems often suffer from:

• insufficient crosslink density,

• molecular chain relaxation,

• SEBS grade incompatibility.

These issues contribute to performance decay, dimensional instability, and inconsistent rebound recovery.

Technical Solutions to Improve EVA Foam Rebound Stability

1. Formulation Optimization

1.1 Enhance Crosslink Density

Increase DCP by 10–20% and add 0.1–0.2 phr TAIC to reinforce the network structure and stabilize long-term foam performance.

1.2 Select High-Rebound SEBS Grades

Use SEBS with strong anti-shrink properties to maintain molecular chain integrity. Combine with higher-hardness SEBS to improve tensile strength and wear resistance.

1.3 Rational Additive Use

Avoid low-molecular-weight plasticizers.

Add 1–2 phr nano CaCO₃ or silica to strengthen the foam skeleton.

Control the foaming ratio between 1.8–2.2 for better pore uniformity.

2. Process Optimization

• Increase curing temperature by 5–10°C (e.g., 160°C → 165–170°C).

• Extend curing time by 3–5 minutes to ensure complete crosslinking.

• Apply secondary aging at 80°C for 2 hours to release internal stress and enhance long-term rebound stability.

Innovative Technology in EVA Foam Materials – Upgrade Performance with Si-TPV 2250 Series Soft-elastic EVA foam modifier

SILIKE’s Si-TPV 2250 Series is an eco-friendly thermoplastic elastomer modifier that redefines EVA chemical foaming technology, ensuring superior foam uniformity and consistency. By preventing chemical migration and providing an adjustable foaming ratio, Si-TPV enhances production efficiency, reduces energy consumption, and improves overall foam performance.

The Si-TPV 2250 Series eco-friendly EVA foam additives enable the production of low-density, high-resilience EVA foams with excellent wear and slip resistance, reduced thermal shrinkage, uniform color, and a high finished product yield. Its ease of processing and cost-efficiency make it a superior alternative to traditional supercritical foaming techniques.

SILIKE’s Si-TPV 2250 Series dynamic vulcanized thermoplastic silicone-based elastomer offers an effective solution for EVA foaming materials, driving advancements in comfort, durability, and sustainability across footwear, sports equipment, medical devices, and packaging applications.

Comparative Study: Effects of Si-TPV 2250-75A vs. Polyolefin Elastomer Additives in EVA Foam (40A Hardness)

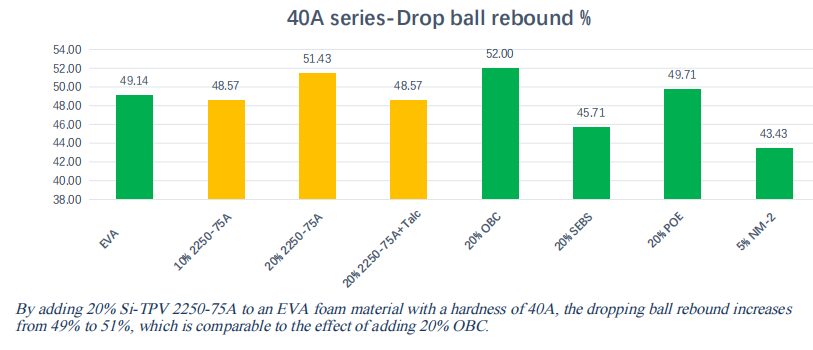

1. Drop Ball Rebound

Adding just 20% Si-TPV 2250-75A to EVA foam (40A hardness) enhances rebound resilience from 49% to 51% — achieving results nearly identical to 20% OBC, while offering improved processing and sustainability benefits.

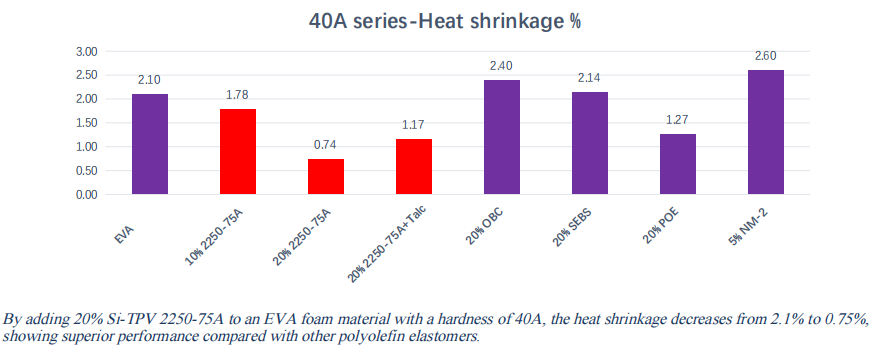

2. Heat Shrinkage

Adding 20% Si-TPV 2250-75A to EVA foam (40A hardness) reduces heat shrinkage from 2.1% to just 0.75% — delivering significantly better dimensional stability than other polyolefin elastomers.

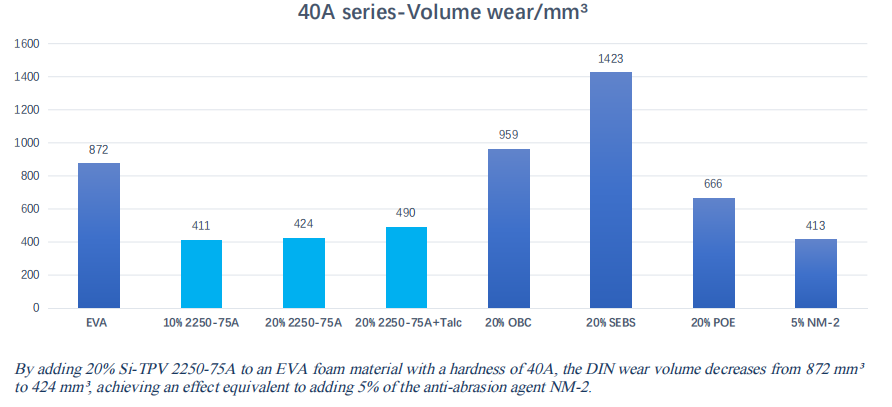

3. DIN Wear Volume

Incorporating 20% Si-TPV 2250-75A into EVA foam (40A hardness) reduces DIN wear from 872 mm³ to 424 mm³ — delivering abrasion resistance comparable to adding 5% anti-wear agent NM-2.

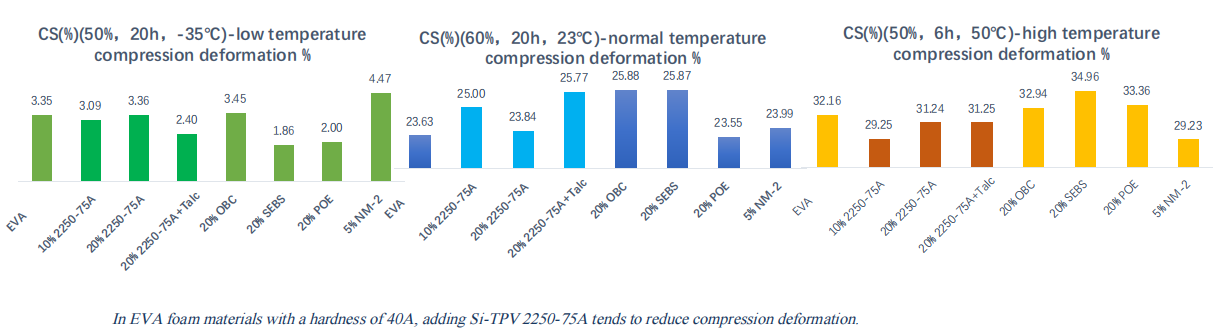

4. Compression Deformation

In EVA foam (40A hardness), the addition of Si-TPV 2250-75A helps reduce compression deformation, enhancing shape recovery and long-term durability.

5. Color Difference

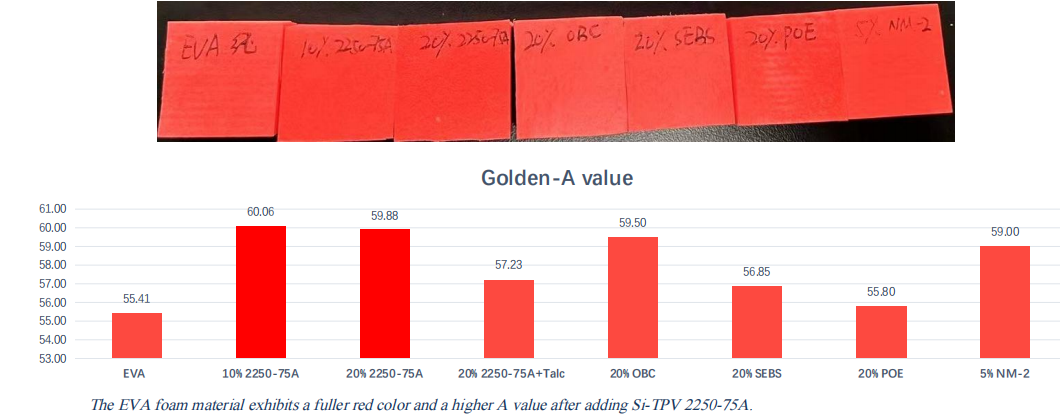

After incorporating Si-TPV 2250-75A, the EVA foam shows a richer red tone and an increased A value, indicating improved color intensity and visual appeal.

Ready to Elevate EVA Foam Materials Performance?

Looking for EVA foams with long-term rebound, excellent wear resistance, and eco-friendly processing? SILIKE’s Si-TPV 2250 Series provides a practical solution to enhance comfort, durability, and production efficiency.

Contact SILIKE to access Si-TPV 2250 Series ultra-light, elastic, and eco-friendly EVA foaming material solutions that enhance sport shoe midsoles, casual footwear, medical insoles, and other applications requiring high-end EVA foams with high rebound,comfort,wear resistance, and sustainability.

Phone: +86-28-83625089 or email: amy.wang@silike.cn. Visit our website: www.si-tpv.com to learn more.