Introduction:

EVA (ethylene vinyl acetate copolymer) foam materials are widely cherished for their lightweight, softness, and affordability, making them a staple in various industries, especially in footwear and sports equipment. However, despite their popularity, these materials often face challenges in meeting the demanding requirements of diverse applications.

Common Challenges in EVA Foamed Materials:

1. Limited Mechanical Properties: Pure EVA foam materials may lack the necessary mechanical strength, tear resistance, and wear resilience required for prolonged use, particularly in high-impact applications like shoe soles and sports mats.

2. Compression Set and Heat Shrinkage: Traditional EVA foams are susceptible to compression set and heat shrinkage over time, leading to dimensional instability and reduced durability, compromising product longevity.

3. Poor Anti-Slip and Anti-Abrasion Performance: In applications where slip resistance and abrasion resistance are critical, such as floor mats and yoga mats, conventional EVA foams may fall short in providing adequate safety and longevity.

EVA Foam Material Solutions:

To address these limitations, EVA is commonly blended with rubbers or thermoplastic elastomers (TPEs). These blends offer improvements in tensile and compression set, tear strength, abrasion resistance, and chemical resilience compared to pure EVA. Additionally, blending with TPEs like thermoplastic polyurethane (TPU) or polyolefin elastomers (POE) enhances viscoelastic properties and facilitates processing and recycling. However, the emergence of olefin block copolymers (OBC) presents a promising alternative, boasting elastomeric characteristics and high-temperature resistance. OBC's unique structure, comprising crystallizable hard segments and amorphous soft segments, enables superior performance in various applications, including improved compression set properties comparable to TPU and TPV.

Innovating EVA foam Material Solutions: SILIKE Si-TPV Modifier

After extensive research and development, SILIKE introduced Si-TPV, a groundbreaking vulcanizate thermoplastic Silicone-based elastomer modifier.

In comparison to modifiers like OBC and POE, Si-TPV offers remarkable advancements in enhancing the properties of EVA foam materials.

SILIKE's Si-TPV modifier offers a groundbreaking solution to address these common challenges in EVA foam Material , elevating the properties and performance of EVA-foamed materials to unprecedented levels.

Here's how the Si-TPV modifier tackles these issues:

1. Reduced Compression Set and Heat Shrinkage Rate: Si-TPV effectively mitigates compression set and heat shrinkage, ensuring dimensional stability and durability, even under prolonged use and varying environmental conditions.

2.Enhanced Elasticity and Softness: The incorporation of Si-TPV enhances the elasticity and softness of EVA foams, providing superior comfort and flexibility, making them ideal for applications requiring a gentle touch.

3.Improved Anti-Slip and Anti-Abrasion Resistance: Si-TPV significantly enhances the anti-slip and anti-abrasion properties of EVA foams, ensuring enhanced safety and longevity, especially in high-traffic areas and intensive use scenarios.

4.Reduced DIN Wear: With Si-TPV, the DIN wear of EVA foams is drastically reduced, indicating superior wear resistance and durability, prolonging the lifespan of end products and minimizing maintenance requirements.

5. Improve the color saturation of EVA foam materials

Applications of Si-TPV-modified EVA foams:

Si-TPV modifier opens up a world of possibilities for EVA-foamed materials, spanning various industries and applications, including:

1. Footwear: Enhanced resilience and durability make Si-TPV-modified EVA foams ideal for shoe soles, from insoles, and midsoles, to outsoles in athletic and casual footwear. providing superior comfort and support for wearers.

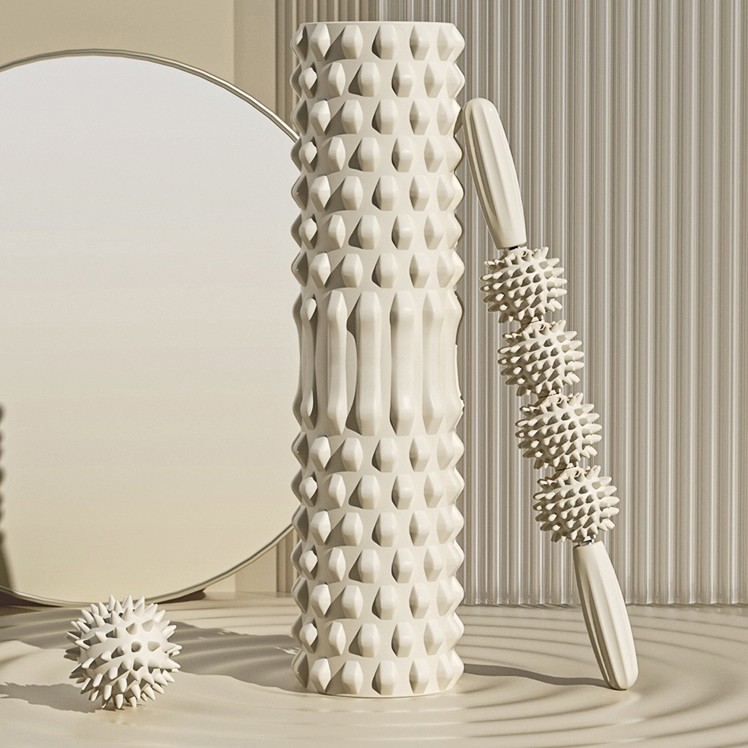

2. Sports Equipment: The combination of elasticity and mechanical strength makes SI-TPV-modified EVA foam suitable for sports mats, padding, and protective gear, providing comfort and safety to athletes.

3. Packaging: Improved compression set and thermal stability make Si-TPV-modified EVA foam suitable for protective packaging materials, ensuring the safe transportation of fragile goods.

4. Sanitary Products: The softness and anti-slip properties of Si-TPV-modified EVA foams make them suitable for sanitary products, ensuring comfort and stability for users.

5. Floor/Yoga Mats: Si-TPV-modified EVA foams offer superior anti-slip and abrasion resistance, making them perfect for floor and yoga mats, providing safety and durability for practitioners.

Conclusion:

Are you ready to revolutionize your EVA foam materials? Don't miss out on the opportunity to elevate your products with the cutting-edge Si-TPV modifier. Reach out to SILIKE to learn more about Si-TPV and how it can enhance your EVA foam manufacturing processes and product quality.

The introduction of the Si-TPV modifier represents a significant breakthrough in enhancing EVA-foamed materials, addressing common challenges and unlocking new possibilities in various industries. By incorporating Si-TPV modifiers into their manufacturing processes, businesses can produce EVA foam materials endowed with enhanced resilience, durability, safety, bright colors, and comfort, catering to diverse applications and driving progress in material science.