Detail

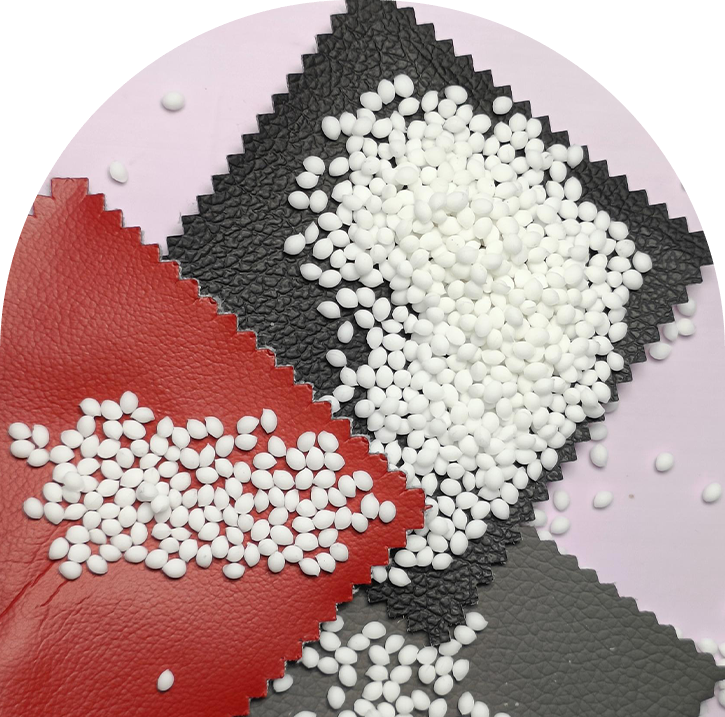

In the world of consumer electronics, aesthetics play a pivotal role in attracting and captivating consumers. One area where this holds especially true is the design of headphones. Over the years, headphones have evolved from purely functional devices to stylish fashion statements. The quest for sleek and visually appealing designs has led to innovations in materials used in their construction. Among these innovations, is Si-TPV, The Soft Touch Revolution material, which allows manufacturers to create aesthetically pleasing headphone designs while ensuring comfort and durability.

Key Benefits

Durability Sustainability

-

Advanced solvent-free technology, without plasticizer, no softening oil, and odorless.

- Environmental protection and recyclability.

- Available in regulatory-compliant formulations

Si-TPV Overmolding Solutions

|

Overmolding recommendations |

||

|

Substrate Material |

Overmold Grades |

Typical Applications |

|

Polypropylene (PP) |

Sport Grips, Leisure Handles,Wearable Devices Knobs Personal Care- Toothbrushes, Razors, Pens, Power & Hand Tool Handles, Grips, Caster Wheels,Toys |

|

|

Polyethylene (PE) |

Gym Gear, Eyewear, Toothbrush Handles,Cosmetic Packaging |

|

|

Polycarbonate (PC) |

Sporting Goods, Wearable Wristbands, Handheld Electronics, Business Equipment Housings, Healthcare Devices, Hand and Power Tools, Telecommunications and Business Machines |

|

|

Acrylonitrile Butadiene Styrene (ABS) |

Sports & Leisure equipment, Wearable Devices, Housewares, Toys, Portable Electronics, Grips, Handles, Knobs |

|

|

PC/ABS |

Sports Gear, Outdoor Equipment,Housewares, Toys, Portable Electronics, Grips, Handles, Knobs, Hand and Power Tools, Telecommunications and Business Machines |

|

|

Standard and Modified Nylon 6, Nylon 6/6, Nylon 6,6,6 PA |

Fitness Goods, Protective Gear, Outdoor Hiking Trekking Equipments, Eyewear, Toothbrush Handles, Hardware, Lawn and Garden Tools, Power Tools |

|

Overmolding Techniques & Adhesion Requirements

SILIKE Si-TPVs Overmolding can adhere to other materials through injection molding. suitable for insert molding and or multiple material molding. Multiple material molding is otherwise known as Multi-shot injection molding, Two-Shot Molding, or 2K molding.

SI-TPVs have excellent adhesion to a variety of thermoplastics, from polypropylene and polyethylene to all kinds of engineering plastics.

When selecting an Si-TPV for an over-molding application, the substrate type should be considered. Not all Si-TPVs will bond to all types of substrates.

For more information regarding specific over-molding Si-TPVs and their corresponding substrate materials, please feel contact us.

Application

Si-TPVs provide a uniquely smooth feel in hardness ranging from Shore A 35 to 90A making them the ideal material to enhance the aesthetics, comfort, and fit of 3C Electronic Products, including hand-held electronics, wearable devices(from phone cases, wristbands, brackets, watch bands, earbuds, necklaces, and AR/VR to silky-smooth parts…), as well as improve scratch resistance and abrasion resistance for the housings, buttons, battery covers and accessory cases of portable devices, consumer electronics, household products, and homewares or other appliances.

Si-TPV offers an exquisitely soft touch feel that surpasses traditional materials. The touch sensation is akin to high-quality silicone rubber, providing an inviting and comfortable user experience.While Si-TPV feels soft and silky, it also exhibits excellent durability. It resists wear and tear, making it ideal for applications on frequently handled devices. Si-TPV ‘s resilience ensures the longevity of the soft touch feel.

Moreover, Si-TPV is recyclable and environmentally friendly, aligning with the increasing emphasis on sustainable manufacturing practices.

Si-TPV will emerge as an innovative solution for soft touch overmolding, to enhance the aesthetics, comfort, and fit of 3C Electronic Products, including hand-held electronics, wearable devices(from phone cases, wristbands, brackets, watch bands, earbuds, necklaces, and AR/VR to silky-smooth parts…), as well as improve scratch resistance and abrasion resistance for the housings, buttons, battery covers and accessory cases of portable devices, consumer electronics, household products, and homewares or other appliances.